Epoxy Mixing Cum Casting Plant

Overview

Resin casting is a method of casting where a mould is filled with a liquid synthetic resin, which then hardens. The synthetic resin for such processes is a monomer for making a thermosetting polymer. During the setting process, the liquid monomer polymerizes into the polymer, thereby hardening into a solid.

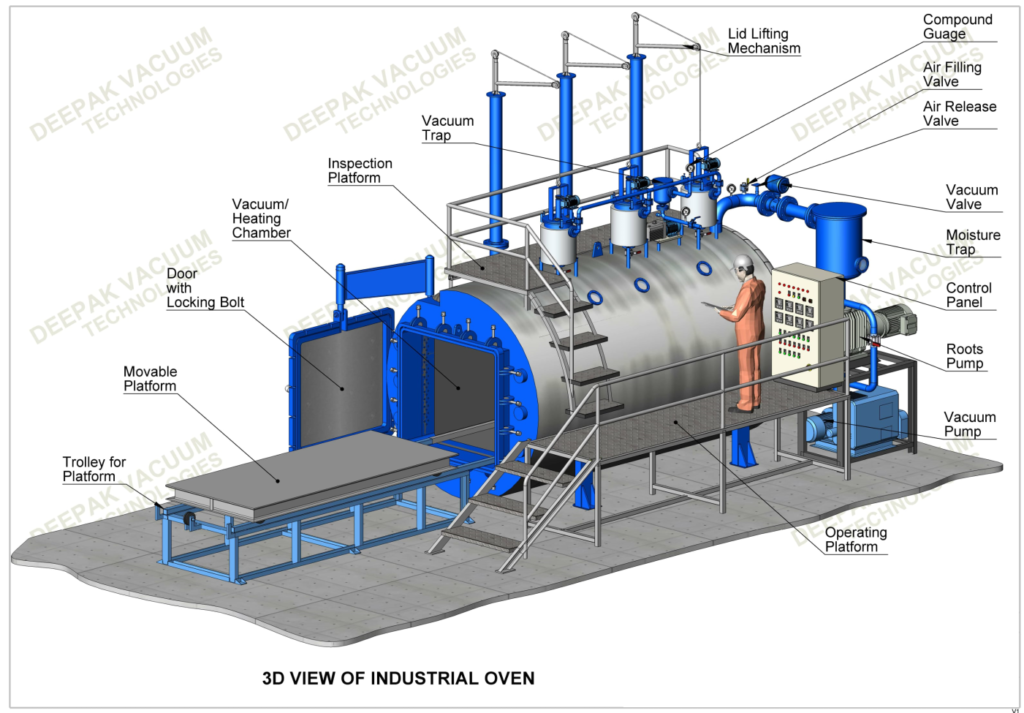

Our resin casting plant is manufactured using quality components and spare parts to ensure optimum performance and long functional life. Resin casting plant is integrated with mixing chamber, which is designed with heating system with temperature controlling arrangement.

The simplest method is gravity casting where the resin is poured into the mold and pulled down into all the parts by gravity inside a vacuum chamber. The casting is done in a vacuum chamber to extract the air which avoids formation of air bubbles.

Features :

- Mixing chamber for mixing of resin, with hardener, accelerators, pigment and filters, of capacities from 5kg to 1000kg, designed for high vacuum degassing.

- It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required.

- Casting chamber, adequately sized to accommodate desired number of moulds, designed for pouring resin under high vacuum.

- Pouring system designed for vacuum casting with easy control and observation from outside, with specially designed PTFE valves.

- The plants can be offered continuous production process.

Applications :

- CT and PT manufacturer

- Dry type transformer etc

Our Gallery

- Epoxy Mixing Cum Casting Plants

- Epoxy Mixing Cum Casting Plants

- Epoxy Mixing Cum Casting Plants

- Epoxy Mixing Cum Casting Plants

- Epoxy Mixing Cum Casting Plants

- Epoxy Mixing Cum Casting Plants

- Epoxy Mixing Cum Casting Plants