Transformer Oil filter plants

Overview

Peculiar Features :

- Sophisticated design. Easy to operate.

- Capacity ranging from 100 LPH to 25000 LPH.

- Imported High quality Filters for best results.

- Negligible Maintenance.

- Easy to replace Filters/heaters

- Digital Temperature monitoring and controlling.

- Can be completely customized as per the requirement of customers, which makes it user friendly.

Technology used :

High Vacuum, Low Temperature. Old technology of heating the oil at maximum temp. To remove water contact from oil was a big failure. In a research it was observed that heating the oil above 60 degree Celsius, started degrading the Cellulose of the oil. For efficient dry out, vacuum in excess of the equilibrium values is required. The drying operation occurs when the oil-cellulose equilibrium condition is disturbed favourably. We strongly recommend our customers for Recirculation of oil through the filter machine. The reason stays simple; the dry oil will be contaminated by the wet windings as they seek equilibrium condition, repeating this cycle many times can correct the situation.

Oil plays an important role in electrical transformers – in fact it is a dual role – as an electrical insulator and as coolant for the transformer. The active life of the transformer mainly depends on the quality of oil it contains. Regular transformer oil filtration assures long and consistent results from the transformer. Transformer oil purification is a process to remove sludge, dissolved moisture and dissolved gases from the oil. Transformer oil conditioning may also include to some extent improving the acidity of the oil. A good oil purification system is able to deliver filtered oil with parameters as per the standard specification.

Optional features :

- Digital Flow meters.

- In-line moisture in oil digital meter.

- Ionic Reaction column to regulate acid content in oil.

- Fully Automatic, PLC control panel.

- Audio (Buzzer) / Visual warnings and process annunciation systems.

- Mobile (Outdoor) type or Vehicle Mounting.

Single Stage :

The Single Stage Transformer Oil Filter Machine is meticulously designed and developed according to the set International standards. Single Stage Transformer Oil Filter Machine will include single stage degassing.

Capacity Range : 50 LPH to 3000 LPH

General Model Name : XS-Li Series

| Parameters | Before Filtration | After Filtration |

|---|---|---|

| Breakdown Voltage (BDV), kV | 10-30 kV | Better than 70 kV |

| Moisture content in Oil, PPM | 50-100 ppm | Less than 5 PPM |

| Gas Content, % Vol | 10% | 0.1% |

| Particle size | 100 Micron | 1 micron |

| Visible Colour of oil | Dark brown with particles | Clear, Light yellow |

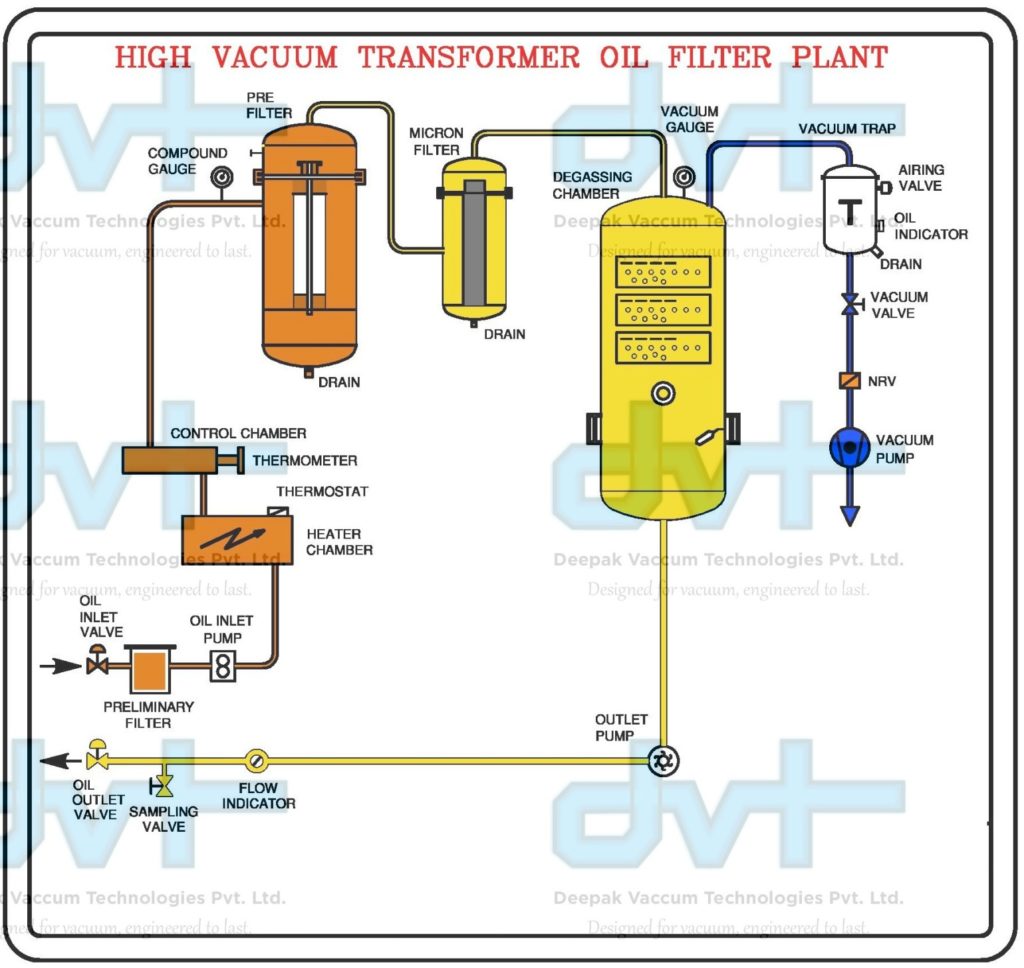

Process Drawing :